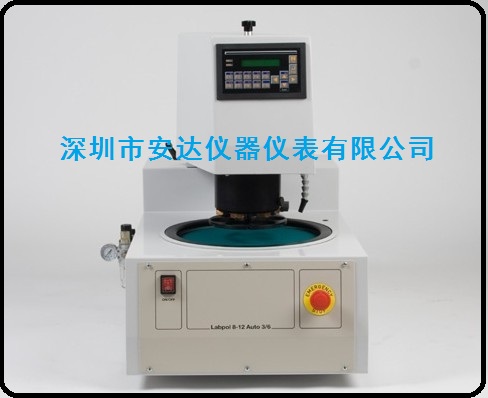

EXTEC ® Labpol 12 - Automatic Grinding/Polishing Machine Catalog# 10400

Advanced Automatic Grinder/Polisher for samples sized up to 2" in diameter. Can be used for automatic and manual grinding and polishing.

The Labpol 12 Auto Grinder/Polisher is an advanced design of Automatic Grinder/Polisher in which polishing or grinding protocols can be created as a program by entering the required parameters on a keypad and then stored for future use.

The base cabinet contains the rotating platen which is driven by a powerful DC motor via a belt drive. This provides adequate torque for grinding 6 samples simultaneously. Platen size of 12" diameter fits onto the platen support. The platen speed is adjustable from 50 rpm to 500 rpm and the platen can be rotated clockwise(CW) or counterclockwise.

The polishing head accepts a sample holder for 6 samples. Sample sized up to 2" diameter can be fitted. The sample holder is rotated at a constant speed by the head motor. An arrangement of 6 air cylinders is located around the rotating specimen holder shaft. The moving pistons in each air cylinder are fully extended by applying airline pressure and locate at the center point of each sample position. In this way each sample is individually loaded. Sample leveling is unnecessary and adaptors are used for a specific sample diameter, thereby reducing the tendency for the samples to tilt during polishing. Because of the individual loading the grinder/polisher can be run with only one sample or as many as six.

The grinding/polishing head can be rotated clear of the cabinet for easy change of platens and so that the unit can be used as for manual or grinding.

Using the Labpol Auto 6 could not be simpler as the system is controlled by a logic controller and the inputs are via a keypad. Program by scrolling through the following parameters:

- PLATEN SPEED

- POLISHING OR GRINDING TIME

- WATER (for grinding)

- PLATEN DIRECTION CW/CCW

- DOSING UNIT (for polishing) ON/OFF

and entering values for a particular protocol.

Up to 8 programs created in this way can be stored and recalled for use as required. The sample loading pressure can also be varied up to 5 bar/75psi.

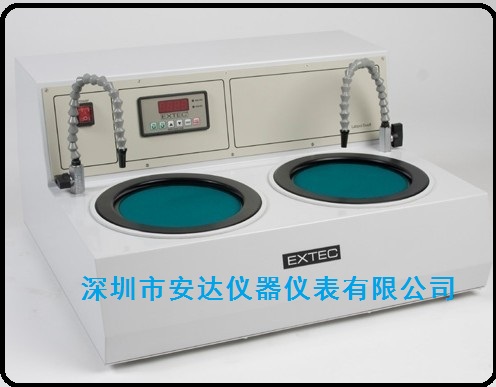

The controlled application (or dosing) of diamond suspensions on a platen during polishing is an essential for reproducible polishing. The Labpol Auto 6 has outputs for the Labpol Dosing Unit.

Two models of dosing unit are available with capacity for 2 or 4 liquid polishing suspensions. Spray jets in each suspension are pressure activated. They are positioned over the platens and deliver drops of liquid at a frequency which has been electronically set. Magnetic stirrers can be optionally fitted under each bottle to keep the suspensions agitated to prevent agglomeration.

- Base Unit

- Motor Drive:

- High torque system with 1.0hp/0.75kW dc motor driving through a 5:1 pulley ration

- Variable Speed Controller:

- Platen Size:

- Auto 6 Polishing Head

- Sample Capacity:

- 6 sample mounts up to 2 inch (50mm) diameter

- Sample Loading:

- individual pneumatic loading

- variable pressure 0-75 psi 0-6 bar

- pressure set on regulator

- Sample Rotation:

- Fixed Speed 120 rpm; 0.25hp/0.18kW ac motor

- Integrated Dispenser

- Air Pressure System:

- comprises 3 standard valves and pressure regulator

- Number of Suspensions:

- Spray Bars:

- two adjustable with platen

- Programming:

- spray time and interval between sprays can be entered on keypad

- Data Input

- Operation of the machine is via operator interface. Main functions selected are:

- Start Cycle

- Select Program 1-8

- Edit Program

- Manual Mode - head disabled

- Parameters to be set for each program are:

- Platen direction, platen speed, time, water On/Off, dispensing paremetrs

- Storage of up to 8 programs

- Dimensions:

- Width: 23 in. (570mm) + 4 in. (100mm) for suspension bottles

- Depth: 30 in. (760mm)

- Height: 28 in. (700mm)

- Weight:

EXTEC ® Labpol 12 - Automatic Grinding/Polishing Machine Catalog# 10400

Advanced Automatic Grinder/Polisher for samples sized up to 2" in diameter. Can be used for automatic and manual grinding and polishing.

The Labpol 12 Auto Grinder/Polisher is an advanced design of Automatic Grinder/Polisher in which polishing or grinding protocols can be created as a program by entering the required parameters on a keypad and then stored for future use.

The base cabinet contains the rotating platen which is driven by a powerful DC motor via a belt drive. This provides adequate torque for grinding 6 samples simultaneously. Platen size of 12" diameter fits onto the platen support. The platen speed is adjustable from 50 rpm to 500 rpm and the platen can be rotated clockwise(CW) or counterclockwise.

The polishing head accepts a sample holder for 6 samples. Sample sized up to 2" diameter can be fitted. The sample holder is rotated at a constant speed by the head motor. An arrangement of 6 air cylinders is located around the rotating specimen holder shaft. The moving pistons in each air cylinder are fully extended by applying airline pressure and locate at the center point of each sample position. In this way each sample is individually loaded. Sample leveling is unnecessary and adaptors are used for a specific sample diameter, thereby reducing the tendency for the samples to tilt during polishing. Because of the individual loading the grinder/polisher can be run with only one sample or as many as six.

The grinding/polishing head can be rotated clear of the cabinet for easy change of platens and so that the unit can be used as for manual or grinding.

Using the Labpol Auto 6 could not be simpler as the system is controlled by a logic controller and the inputs are via a keypad. Program by scrolling through the following parameters:

- PLATEN SPEED

- POLISHING OR GRINDING TIME

- WATER (for grinding)

- PLATEN DIRECTION CW/CCW

- DOSING UNIT (for polishing) ON/OFF

and entering values for a particular protocol.

Up to 8 programs created in this way can be stored and recalled for use as required. The sample loading pressure can also be varied up to 5 bar/75psi.

The controlled application (or dosing) of diamond suspensions on a platen during polishing is an essential for reproducible polishing. The Labpol Auto 6 has outputs for the Labpol Dosing Unit.

Two models of dosing unit are available with capacity for 2 or 4 liquid polishing suspensions. Spray jets in each suspension are pressure activated. They are positioned over the platens and deliver drops of liquid at a frequency which has been electronically set. Magnetic stirrers can be optionally fitted under each bottle to keep the suspensions agitated to prevent agglomeration.

- Base Unit

- Motor Drive:

- High torque system with 1.0hp/0.75kW dc motor driving through a 5:1 pulley ration

- Variable Speed Controller:

- Platen Size:

- Auto 6 Polishing Head

- Sample Capacity:

- 6 sample mounts up to 2 inch (50mm) diameter

- Sample Loading:

- individual pneumatic loading

- variable pressure 0-75 psi 0-6 bar

- pressure set on regulator

- Sample Rotation:

- Fixed Speed 120 rpm; 0.25hp/0.18kW ac motor

- Integrated Dispenser

- Air Pressure System:

- comprises 3 standard valves and pressure regulator

- Number of Suspensions:

- Spray Bars:

- two adjustable with platen

- Programming:

- spray time and interval between sprays can be entered on keypad

- Data Input

- Operation of the machine is via operator interface. Main functions selected are:

- Start Cycle

- Select Program 1-8

- Edit Program

- Manual Mode - head disabled

- Parameters to be set for each program are:

- Platen direction, platen speed, time, water On/Off, dispensing paremetrs

- Storage of up to 8 programs

- Dimensions:

- Width: 23 in. (570mm) + 4 in. (100mm) for suspension bottles

- Depth: 30 in. (760mm)

- Height: 28 in. (700mm)

- Weight:

EXTEC ® Labpol 12 - Automatic Grinding/Polishing Machine Catalog# 10400

Advanced Automatic Grinder/Polisher for samples sized up to 2" in diameter. Can be used for automatic and manual grinding and polishing.

The Labpol 12 Auto Grinder/Polisher is an advanced design of Automatic Grinder/Polisher in which polishing or grinding protocols can be created as a program by entering the required parameters on a keypad and then stored for future use.

The base cabinet contains the rotating platen which is driven by a powerful DC motor via a belt drive. This provides adequate torque for grinding 6 samples simultaneously. Platen size of 12" diameter fits onto the platen support. The platen speed is adjustable from 50 rpm to 500 rpm and the platen can be rotated clockwise(CW) or counterclockwise.

The polishing head accepts a sample holder for 6 samples. Sample sized up to 2" diameter can be fitted. The sample holder is rotated at a constant speed by the head motor. An arrangement of 6 air cylinders is located around the rotating specimen holder shaft. The moving pistons in each air cylinder are fully extended by applying airline pressure and locate at the center point of each sample position. In this way each sample is individually loaded. Sample leveling is unnecessary and adaptors are used for a specific sample diameter, thereby reducing the tendency for the samples to tilt during polishing. Because of the individual loading the grinder/polisher can be run with only one sample or as many as six.

The grinding/polishing head can be rotated clear of the cabinet for easy change of platens and so that the unit can be used as for manual or grinding.

Using the Labpol Auto 6 could not be simpler as the system is controlled by a logic controller and the inputs are via a keypad. Program by scrolling through the following parameters:

- PLATEN SPEED

- POLISHING OR GRINDING TIME

- WATER (for grinding)

- PLATEN DIRECTION CW/CCW

- DOSING UNIT (for polishing) ON/OFF

and entering values for a particular protocol.

Up to 8 programs created in this way can be stored and recalled for use as required. The sample loading pressure can also be varied up to 5 bar/75psi.

The controlled application (or dosing) of diamond suspensions on a platen during polishing is an essential for reproducible polishing. The Labpol Auto 6 has outputs for the Labpol Dosing Unit.

Two models of dosing unit are available with capacity for 2 or 4 liquid polishing suspensions. Spray jets in each suspension are pressure activated. They are positioned over the platens and deliver drops of liquid at a frequency which has been electronically set. Magnetic stirrers can be optionally fitted under each bottle to keep the suspensions agitated to prevent agglomeration.

- Base Unit

- Motor Drive:

- High torque system with 1.0hp/0.75kW dc motor driving through a 5:1 pulley ration

- Variable Speed Controller:

- Platen Size:

- Auto 6 Polishing Head

- Sample Capacity:

- 6 sample mounts up to 2 inch (50mm) diameter

- Sample Loading:

- individual pneumatic loading

- variable pressure 0-75 psi 0-6 bar

- pressure set on regulator

- Sample Rotation:

- Fixed Speed 120 rpm; 0.25hp/0.18kW ac motor

- Integrated Dispenser

- Air Pressure System:

- comprises 3 standard valves and pressure regulator

- Number of Suspensions:

- Spray Bars:

- two adjustable with platen

- Programming:

- spray time and interval between sprays can be entered on keypad

- Data Input

- Operation of the machine is via operator interface. Main functions selected are:

- Start Cycle

- Select Program 1-8

- Edit Program

- Manual Mode - head disabled

- Parameters to be set for each program are:

- Platen direction, platen speed, time, water On/Off, dispensing paremetrs

- Storage of up to 8 programs

- Dimensions:

- Width: 23 in. (570mm) + 4 in. (100mm) for suspension bottles

- Depth: 30 in. (760mm)

- Height: 28 in. (700mm)

- Weight:

金相切片研磨抛光机AD-2P

$200mm

双盘双控研磨抛光机AD-2P无级变速

$200mm

研磨抛光机AD-2P

$AD-2P

美国EXTEC全自动研磨抛光机Labpol 12-3DI

$Labpol 12-3DI

美国EXTEC全自动研磨抛光机Labpol 12

$Labpol 12

美国EXTEC双盘研究抛光机10248

$10248

美国EXTEC研磨抛光机10200

$10200

美国EXTEC镶嵌机10104

$10104

双盘研磨抛光机AD-2P

$AD-2P

单盘研磨抛光机AD-1P

$AD-1P