SMD-V离子污染测试仪为美国2015年新款型号

SCS在多种工业领域(包括印制电路板、生产和医药工业)为非破坏性过程控制测试提供全范围的离子测试系统。SCS仪器集团离子污染测试系统是一个设计为快速、准确离子污染清洁度测试的模组组装系统。每一个模组使用超净酒精/水萃取介质和专利的动态方式来快速、无破坏性测试产品样品。

Ionograph SMD-V模组有一台个人电脑Ionograph SMD-V指令模组操纵来测定是否符合IPC-650和其他工业标准的清洁度需要。他们可用于测量输入电子元器件和电路板的品质并且可以评估助焊污染和监视表面清洁度。

SMD-V是最多用的测试模组。此模组具有18u‘‘*20u‘‘、20u‘‘*26u‘‘、26u‘‘*30u‘‘和26u‘‘*38u‘‘的测试腔室尺寸,可以依据负载需要操作于部分或全溶液模式。浸入式搅拌喷嘴和溶液加热器使这种大型测试模组具有卓越的敏感度,高效的工作和轻松准确的测试超细间距元器件的能力。依据ANSI/J-STD001的标准。

|

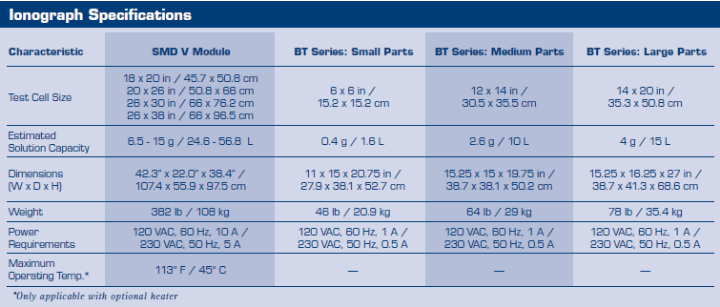

Ionograph规范

|

|

规格大小

|

18 x 20 in / 45.7 x 50.8 cm

20 x 26 in / 50.8 x 66 cm

26 x 30 in / 66 x 76.2 cm

26 x 38 in / 66 x 96.5 cm

|

|

解决方案

|

6.5 - 15 g / 24.6 - 56.8 L

|

|

外观

|

42.3” x 22.0” x 38.4” /107.4 x 55.9 x 97.5 cm

|

|

重量

|

382 lb / 108 kg

|

|

电力需求

|

120 VAC, 60 Hz, 10 A /230 VAC, 50 Hz, 5 A

|

|

操作温度

|

113°F / 45° C

|

SCS Ionograph Test Systems

SCS offers a full range of capacity and control to meet the needs of any lab or manufacturer. Designed for fast and accurate ionic contamination cleanliness testing, SCS Ionographs:

• Determine the cleanliness of electronic components, assemblies with SMT devices, and bare and assembled printed circuit boards.

• Provide an accurate, repeatable and rapid method for determining cleanliness on location.

• Provide immediate process control results, negating the need for outside laboratory testing.

• Verify proper cleanliness of surfaces prior to the application of conformal coatings or potting compounds.

• Comply with industrial specifications such as ANSI/J-STD-001 and IPC-TM-650, and are specifically named in MIL-STD-2000A and

MIL-P-28809A.

SCS Ionograph SMD V

SCS Ionograph SMD V is a floor unit commonly used for larger circuit boards in high-volume production environments. Submerged agitation jets and optional heated extract solution provide outstanding sensitivity, operational efficiency and the ability to test ultra-fine pitch components with ease and accuracy.

The SCS Ionograph SMD V offers users the ability to test components with an optional heated or non-heated test solution. IPC-TM-650 describes the benefit of a heated solution to “accelerate and improve the efficiency of extraction of ionic material from poorly accessible regions, such as under surface-mounted components.” In addition to increasing cleaning efficiency, a heated system also ensures temperature consistency of the test solution, whereas solution temperature in an unheated

system can vary due to circulation pump friction created during the testing process.

The CE-certified SMD V model is available with a convenient onboard all-in-one computer or tablet, providing efficient control and monitoring of the test system using Windows®-based SCS PowerView™ software. The system features

easy-access door panels for routine maintenance

of consumable components (e.g., DI columns

and pump filter).

SCS在多种工业领域(包括印制电路板、生产和医药工业)为非破坏性过程控制测试提供全范围的离子测试系统。SCS仪器集团离子污染测试系统是一个设计为快速、准确离子污染清洁度测试的模组组装系统。每一个模组使用超净酒精/水萃取介质和专利的动态方式来快速、无破坏性测试产品样品。

Ionograph SMD-V模组有一台个人电脑Ionograph SMD-V指令模组操纵来测定是否符合IPC-650和其他工业标准的清洁度需要。他们可用于测量输入电子元器件和电路板的品质并且可以评估助焊污染和监视表面清洁度。

SMD-V是最多用的测试模组。此模组具有18u‘‘*20u‘‘、20u‘‘*26u‘‘、26u‘‘*30u‘‘和26u‘‘*38u‘‘的测试腔室尺寸,可以依据负载需要操作于部分或全溶液模式。浸入式搅拌喷嘴和溶液加热器使这种大型测试模组具有卓越的敏感度,高效的工作和轻松准确的测试超细间距元器件的能力。依据ANSI/J-STD001的标准。

|

Ionograph规范

|

|

规格大小

|

18 x 20 in / 45.7 x 50.8 cm

20 x 26 in / 50.8 x 66 cm

26 x 30 in / 66 x 76.2 cm

26 x 38 in / 66 x 96.5 cm

|

|

解决方案

|

6.5 - 15 g / 24.6 - 56.8 L

|

|

外观

|

42.3” x 22.0” x 38.4” /107.4 x 55.9 x 97.5 cm

|

|

重量

|

382 lb / 108 kg

|

|

电力需求

|

120 VAC, 60 Hz, 10 A /230 VAC, 50 Hz, 5 A

|

|

操作温度

|

113°F / 45° C

|

SCS在多种工业领域(包括印制电路板、生产和医药工业)为非破坏性过程控制测试提供全范围的离子测试系统。SCS仪器集团离子污染测试系统是一个设计为快速、准确离子污染清洁度测试的模组组装系统。每一个模组使用超净酒精/水萃取介质和专利的动态方式来快速、无破坏性测试产品样品。

Ionograph SMD-V模组有一台个人电脑Ionograph SMD-V指令模组操纵来测定是否符合IPC-650和其他工业标准的清洁度需要。他们可用于测量输入电子元器件和电路板的品质并且可以评估助焊污染和监视表面清洁度。

SMD-V是最多用的测试模组。此模组具有18u‘‘*20u‘‘、20u‘‘*26u‘‘、26u‘‘*30u‘‘和26u‘‘*38u‘‘的测试腔室尺寸,可以依据负载需要操作于部分或全溶液模式。浸入式搅拌喷嘴和溶液加热器使这种大型测试模组具有卓越的敏感度,高效的工作和轻松准确的测试超细间距元器件的能力。依据ANSI/J-STD001的标准。

|

Ionograph规范

|

|

规格大小

|

18 x 20 in / 45.7 x 50.8 cm

20 x 26 in / 50.8 x 66 cm

26 x 30 in / 66 x 76.2 cm

26 x 38 in / 66 x 96.5 cm

|

|

解决方案

|

6.5 - 15 g / 24.6 - 56.8 L

|

|

外观

|

42.3” x 22.0” x 38.4” /107.4 x 55.9 x 97.5 cm

|

|

重量

|

382 lb / 108 kg

|

|

电力需求

|

120 VAC, 60 Hz, 10 A /230 VAC, 50 Hz, 5 A

|

|

操作温度

|

113°F / 45° C

|

离子污染测试仪 美国SCS原装进口

$离子污染测试仪

美国SCS离子污杂测试仪Ionograph SMD V(动态测试/线路板检测专用…

$SCS Ionograph SMD V

SCS Ionograph离子污染测试仪

$SCS Ionograph离子污染测试仪

美国SCS离子污染测试仪

$美国SCS离子污染测试仪

SCS Ionograph BT离子污染测试仪

$SCS Ionograph BT

离子污染测试仪SCS Ionograph SMD V

$Ionograph SMD V

离子污染测试仪SCS Ionograph BT MP

$Ionograph BT MP

离子污染测试仪SCS Ionograph BT LP

$SCS Ionograph BT LP

SCS Ionograph BT LP离子污染测试仪

$SCS Ionograph BT LP

Ionograph BT离子污染测试机

$Ionograph BT